Tips for Reducing Electronic Component Failure in OEM Products

How OEMs Can Reduce Electronic Component Failure

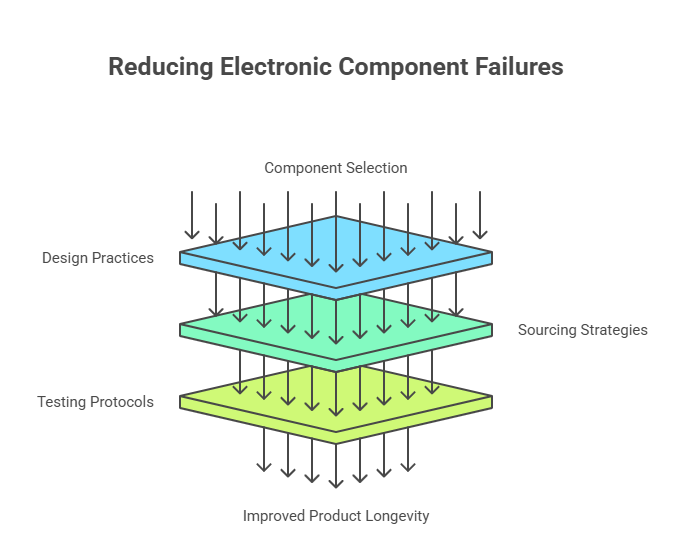

Electronic component failure is a major concern for OEMs, impacting product reliability, warranty costs, and customer satisfaction. Using high-quality components is essential, but implementing best practices in design, sourcing, and testing can further minimize failures. Here’s a complete guide for engineers and OEMs to reduce component failures and improve product longevity.

1. Source High-Quality Components

Always procure components from trusted distributors like DDS International – Edzeal. Genuine capacitors, resistors, switches, ICs, and connectors ensure better performance and lower failure rates.

2. Verify Specifications and Datasheets

Check voltage ratings, capacitance, ESR, and tolerance values. Using components outside their recommended specifications is a leading cause of failures.

3. Proper Storage and Handling

Components like electrolytic capacitors, ICs, and semiconductors are sensitive to moisture, heat, and static. Follow proper storage, ESD precautions, and handling procedures.

4. Adequate Thermal Management

Overheating shortens component lifespan. Use heat sinks, proper PCB layout, and cooling solutions to maintain optimal operating temperatures.

5. Correct Circuit Design

Ensure correct voltage, current, and polarity for capacitors and diodes. Avoid overloading resistors and ICs. Proper PCB trace widths and spacing also reduce failure risks.

6. Regular Testing and Quality Checks

Perform functional tests, in-circuit testing, and accelerated life testing to catch weak or faulty components before assembly or shipping.

7. Avoid Counterfeit Components

Counterfeit or substandard components can fail quickly. Always purchase from authorized distributors and verify part authenticity with datasheets and certifications.

8. Use Protective Circuitry

Incorporate fuses, surge protectors, and voltage regulators to prevent damage from electrical spikes and transients.

Conclusion

Minimizing electronic component failure is critical for OEMs to deliver reliable products and maintain customer trust. By sourcing genuine components, following best design practices, and implementing thorough testing, OEMs can ensure long-lasting and high-performing devices.

Buy High-Quality Components from DDS International – Edzeal

Partner with DDS International – Edzeal for authentic capacitors, resistors, switches, ICs, and connectors. With verified datasheets, OEM pricing, and fast delivery across India, we help reduce failure rates and improve product reliability.

FAQs

Q1. What causes electronic component failure in OEM products?

Incorrect specifications, overheating, poor handling, or counterfeit components.

Q2. How can OEMs reduce failures?

By sourcing genuine components, proper design, testing, and thermal management.

Q3. Where to buy high-quality components in India?

From authorized distributors like DDS International – Edzeal.