No products in the cart.

How Price Fluctuations in Electronic Components Impact OEM Production Planning

Understanding the Effects of Component Price Changes on OEM Manufacturing Efficiency

In the fast-moving electronics industry, price stability is a rare luxury. Component prices can fluctuate due to global shortages, material costs, currency shifts, and geopolitical factors. For OEMs, these price changes can significantly affect production planning, costing, and delivery schedules. Understanding how to manage and respond to these fluctuations is critical to maintaining profitability and operational stability.

Why Component Prices Fluctuate

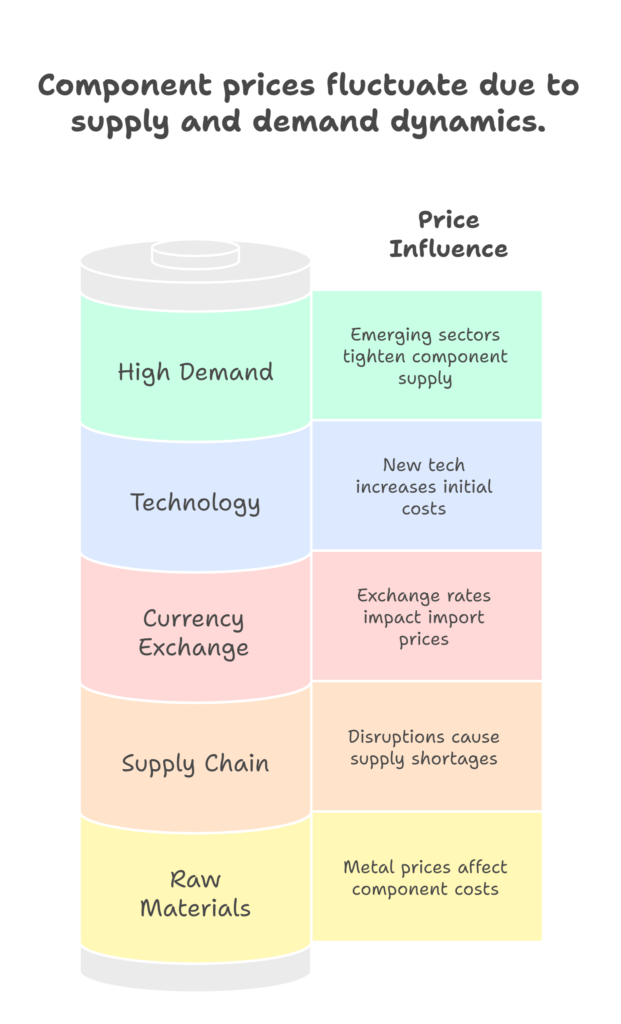

Electronic component pricing depends on several dynamic factors. Key reasons include:

- Raw Material Costs: The prices of metals like copper, aluminum, and gold influence capacitor, connector, and resistor costs.

- Global Supply Chain Disruptions: Events such as pandemics, trade restrictions, or shipping delays create supply shortages, pushing prices up.

- High Demand from Emerging Sectors: The rise of EVs, IoT, and AI devices increases global demand for components, tightening supply.

- Currency Exchange Rates: Imported components fluctuate in price depending on international exchange rate movements.

- Technological Advancements: Newer, smaller, and more efficient components often cost more during early adoption phases.

How Price Volatility Affects OEM Production Planning

OEMs depend on predictable pricing to plan their budgets and production schedules. When component prices fluctuate, it can cause:

- Increased Production Costs: Even a small price hike in capacitors or resistors can raise total project costs for large-scale OEMs.

- Disrupted Procurement Schedules: Frequent price changes make it difficult to forecast purchase timelines and quantities.

- Inventory Challenges: OEMs may overstock during low prices or face shortages when prices surge unexpectedly.

- Reduced Profit Margins: If selling prices are fixed, rising component costs can erode profits.

Strategies for OEMs to Manage Component Price Fluctuations

1. Partner with Trusted Distributors

Working with authorised and established distributors like DDS International – Edzeal ensures transparent pricing and reliable supply. Authorised partners offer bulk pricing, genuine components, and advance updates on market trends.

2. Opt for Long-Term Contracts

Signing fixed-price or volume-based agreements helps stabilize procurement costs. OEMs can negotiate better rates by committing to consistent purchase volumes.

3. Monitor Market Trends

Keeping track of global electronic component trends and raw material indices helps OEMs anticipate upcoming price shifts. This allows proactive planning instead of reactive adjustments.

4. Maintain Strategic Inventory

Building a buffer stock of frequently used components can shield production from short-term price spikes. However, inventory levels should align with shelf life and storage conditions.

5. Diversify the Supplier Base

Relying on multiple suppliers prevents total dependence on one source. This helps OEMs balance cost fluctuations and maintain consistent supply during disruptions.

6. Use Data-Driven Forecasting

Modern ERP and AI tools can analyze market patterns, helping OEMs forecast demand and budget efficiently. Predictive analytics improve procurement timing and cost control.

Role of Authorised Distributors in Price Stability

Partnering with authorised distributors like DDS International – Edzeal ensures you receive stable pricing, verified datasheets, and genuine components. With access to top brands such as JWCO, DVAN, NDF,HKR and Edzeal, OEMs can confidently plan long-term production without worrying about counterfeit or inconsistent supplies.

How DDS International – Edzeal Helps OEMs Stay Ahead

As a leading electronic components distributor in India since 2009, DDS International – Edzeal provides:

- Reliable stock availability for bulk and OEM orders

- Competitive and stable pricing on all components

- Fast, pan-India delivery for time-sensitive production

- Technical datasheets and guidance for accurate sourcing

Conclusion

Component price fluctuations are inevitable, but OEMs can minimize their impact through smart planning, supplier diversification, and partnerships with authorised distributors. With the right sourcing strategy and reliable partners like DDS International – Edzeal, manufacturers can ensure stable production, better cost control, and long-term business growth.